fast mould change expanded polypropylene epp foam molding machine for EPP airplane foam

fast mould change expanded polypropylene epp foam molding machine for EPP airplane foamEPP moulding machine main features:1. Feeding methods: Feeding ...

fast mould change expanded polypropylene epp foam molding machine for EPP airplane foam

EPP moulding machine main features:

1. Feeding methods:

Feeding by pulse,

Feeding by negative pressure,

Feeding by back pressure,

Feeding assisted by currents of wind.

2. Smart proportional valves of high precision are in control of such processing as feeding, heating and mould unloading.

3. Intensive hydraulic power system offers the integration of powering and pressurization, thus securing convenience for maintenance.

4. Fast mold change system with EPP moulding machine,

5. Self-equipped water tank (steam chest) .

6. Precise joint retention accuracy, with the margin of range lesser than 0.5mm.

7. Frames of high rigidity, promise and secure enduring production in responsive to EPP mouling machine industry.

8. Various devices for safety.

EPP moulding machine products

EPP packaging

EPP unmanned aircraft crates EPP portable kettle EPP thermostatic red wine thermos pot EPP vegetable packaging

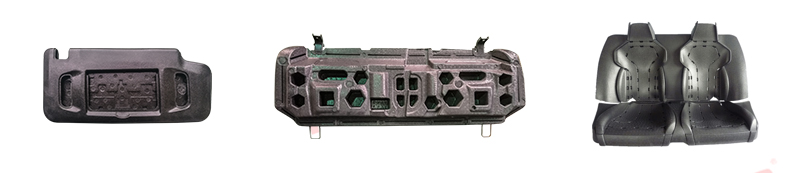

EPP car part

EPP Sun Visor EPP seat headrest EPP seat

EPP toolbox EPP car bumper cushion

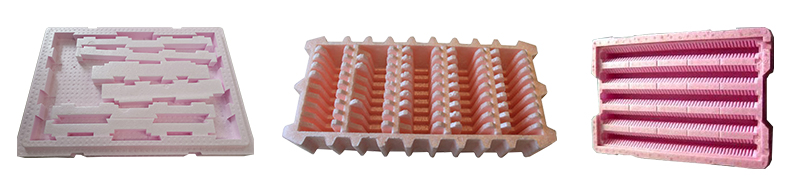

EPP electronic field

Electronic Packaging pad Liquid wafer turnover box Electronic Packaging

EPP civil field

EPP building blocks Helmet EPP surfboard EPP airplane foam

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

CATEGORIES

LATEST NEWS

- Introduction to the main functions of PbootCMS

SPZ-FHO/FHOY Vacuum Molding Machines: The Future of High-Efficiency, Low-Cost Production

- Introduction to the main functions of PbootCMS

SPZ-FHOY: Reliable and Efficient Molding Machine for Diverse Manufacturing Needs

- Introduction to the main functions of PbootCMS

SPZ-FHO: Advanced Vacuum Molding Technology for High-Precision Applications

- Introduction to the main functions of PbootCMS

SPZ-FHOY: The Advanced One-Button Mold Locking Machine for Modern Manufacturing

CONTACT US

Contact: Mr Zhang

Phone: +86-15010314731

Tel: +86-15010314731

Email: [email protected]

Add: Xuanwu Lake, Xuanwu District, Nanjing City, Jiangsu Province