Expanded Polystyrene Styrofoam Moulding Machine With Hydraulic System

Expanded Polystyrene Styrofoam Moulding Machine With Hydraulic System

The expanded polystyrene styrofoam moulding machine with hydraulic system is new product, the expanded styrofoam moulding machine has long service life, uninterrupted performance and efficient operation. Please rest assured to buy it.

The polystyrene molding machine has these main features:

Machine structure:

a. All frames of moulding machine with hydraulic system are welded onto strong rectangle tubes which are processed by heat treatment to prevent the deformation of the mould panel.

b. After heat treatment, all frames are processed by sand blasting treatment to get rust prevention, so anti-corrosive primer and finishing coat are greatly improved ensuring anti-corrosion performance and extended life of expanded polystyrene styrofoam moulding machine.

Electronic control:

a. The thermocol block moulding machine adopts PLC (Mitsubishi) and touch screen (Schneider), for close-mold, filling, heating, cooling, de-mould, the whole process is automatic.

b. All electronic components are from famous brands schneider, omron, german, gauge, ensuring to increase the stability of EPS shape moulding machine.

c. Adopts PLC controller, to set the digital coder, for easy adjustment, and make the shape molding machine has more precise control.

Note:

❉ The automatic molding machine id divided into type A and B.

Type A: Mechanical de-mould ejecting device

Type B: Hydraulic cylinder de-mould ejector device

❉ Extension of machine base height is optional.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

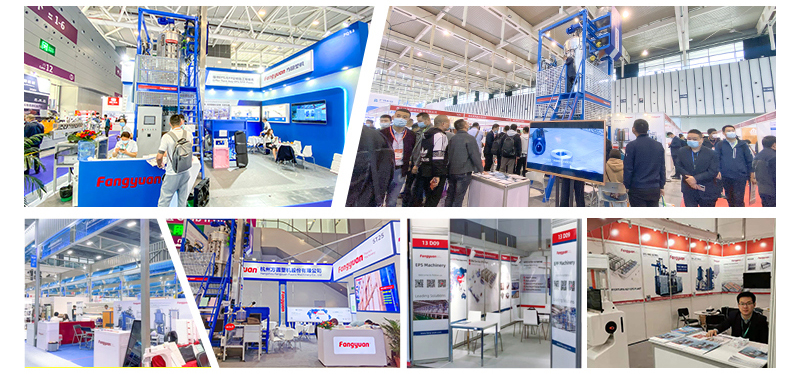

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

CATEGORIES

LATEST NEWS

- Introduction to the main functions of PbootCMS

SPZ-FHO/FHOY Vacuum Molding Machines: The Future of High-Efficiency, Low-Cost Production

- Introduction to the main functions of PbootCMS

SPZ-FHOY: Reliable and Efficient Molding Machine for Diverse Manufacturing Needs

- Introduction to the main functions of PbootCMS

SPZ-FHO: Advanced Vacuum Molding Technology for High-Precision Applications

- Introduction to the main functions of PbootCMS

SPZ-FHOY: The Advanced One-Button Mold Locking Machine for Modern Manufacturing

CONTACT US

Contact: Mr Zhang

Phone: +86-15010314731

Tel: +86-15010314731

Email: [email protected]

Add: Xuanwu Lake, Xuanwu District, Nanjing City, Jiangsu Province